Description

New Mitutoyo 35 Pc Rectangular GRADE 3 Gage Block Set. 516-915 made in Japan. Sealed in the box. The one in the photos was opened for the photos ,you will receive a new sealed one!

Product Description

516-915-26 Mitutoyo 35 Piece Steel Rectangular Gage Block Set: Grade AS-1 ( 3 ) .

The Mitutoyo 516-915 rectangular steel gage block set has the following specifications:

-

Number of Blocks: 35 Pieces

-

Grade: AS-1 ( Grade 3 )

-

Material: Steel

The 35 Piece Square Gage Block Set is made up of the following blocks:

-

.10005″

-

9 Blocks: .1001-.1009″ (.0001″)

-

9 Blocks: .101-.109″ (.001″)

-

9 Blocks: .11-.19″ (.01″)

-

3 Blocks: .1-.3″ (.1″)

-

4 Blocks: .500″, 1″, 2″, 4″

Features:

-

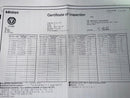

Provided with Inspection Certificate

-

Specific, repeated heat treatment of steel blocks reduce deterioration change over time

-

Advanced lapping techniques achieve the best flatness, surface roughness needed for gage blocks

-

Black characters on gage blocks are inscribed by laser and clearly visible

-

Rectangular base for accurate wringing

-

Nominal length indicated with laser-etched, black characters

-

Provided with Inspection Certificate

-

Supplied in a solid wooden case

The Mitutoyo 516-915 rectangular gage block set provides exceptional accuracy for essential manufacturing quality control on dimensional parts. Mitutoyo Rectangular Gage Block sets offer exceptional precision and stability for calibration and manufacturing traceability of standard-sized pieces. Gage block sets are available in different grades, sizes and steps, offering exceptional precision and stability for calibration and manufacturing traceability. The Mitutoyo innovative lapping technique makes our gage blocks some of the most accurate and trusted instruments in the world, featuring exceptional flatness and ideal surface roughness. Steel gage blocks are constructed of high-carbon, high-chrome steel . A rectangular gage block can retain stable orientation both longitudinally and laterally. A wide range of application measurements can be made, including cutting tool positioning, angle measurement using a sign bar, taper measuring with a roller, and inspection of depth micrometers.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.